|

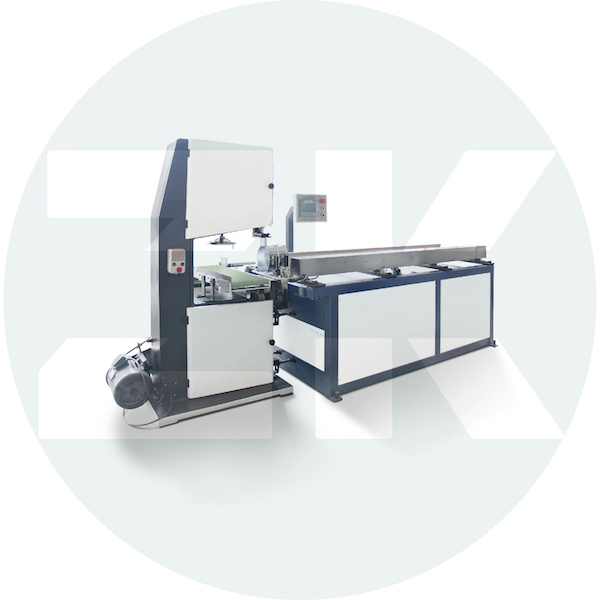

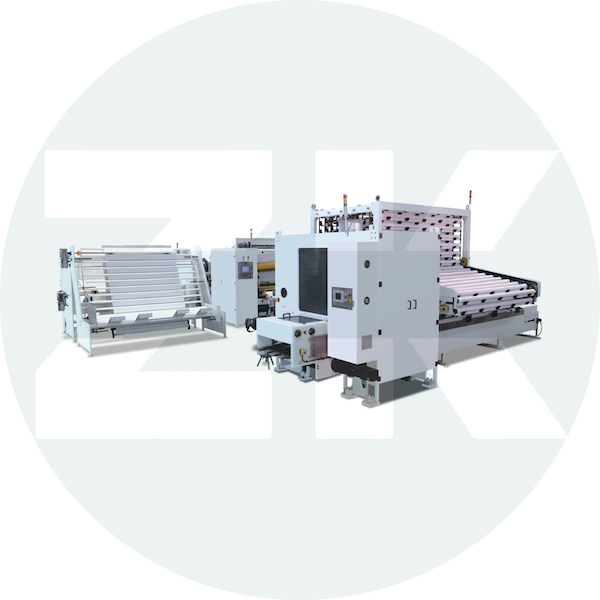

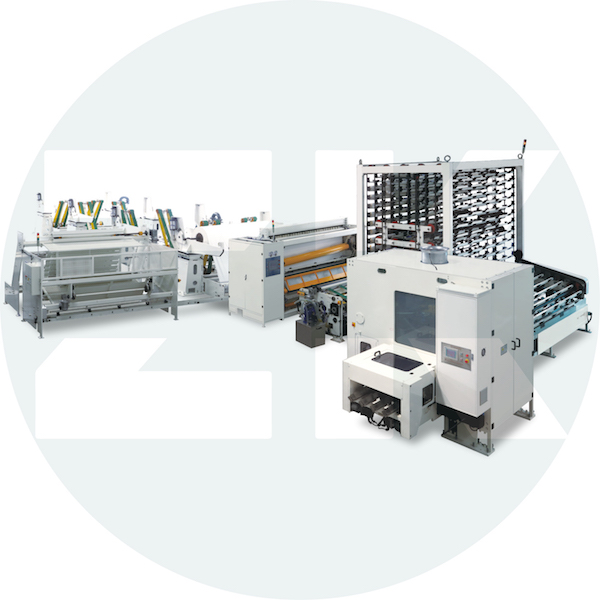

ZM-OK Log Saw Automatic Cutting Machine (integrated to toilet paper rewinder) |

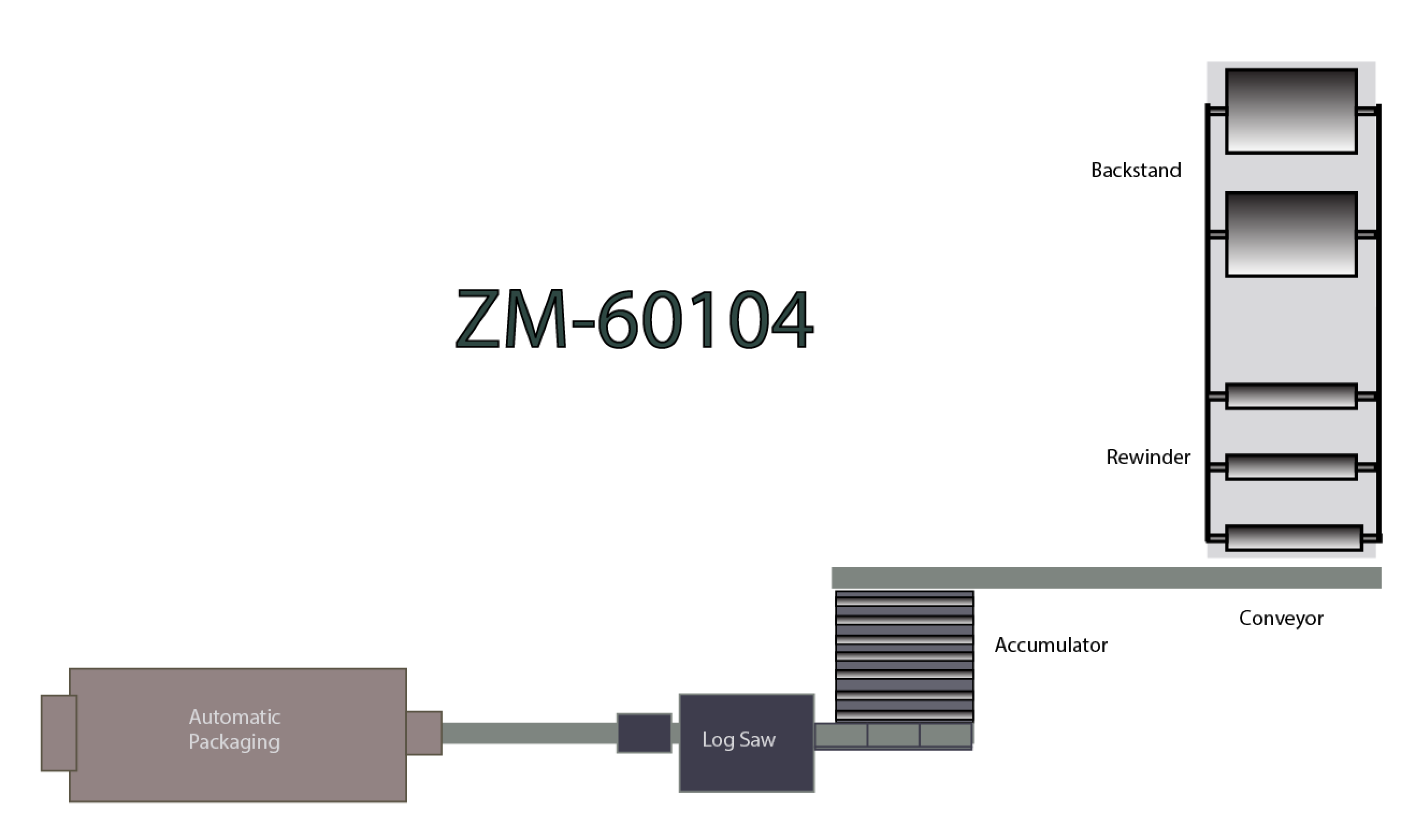

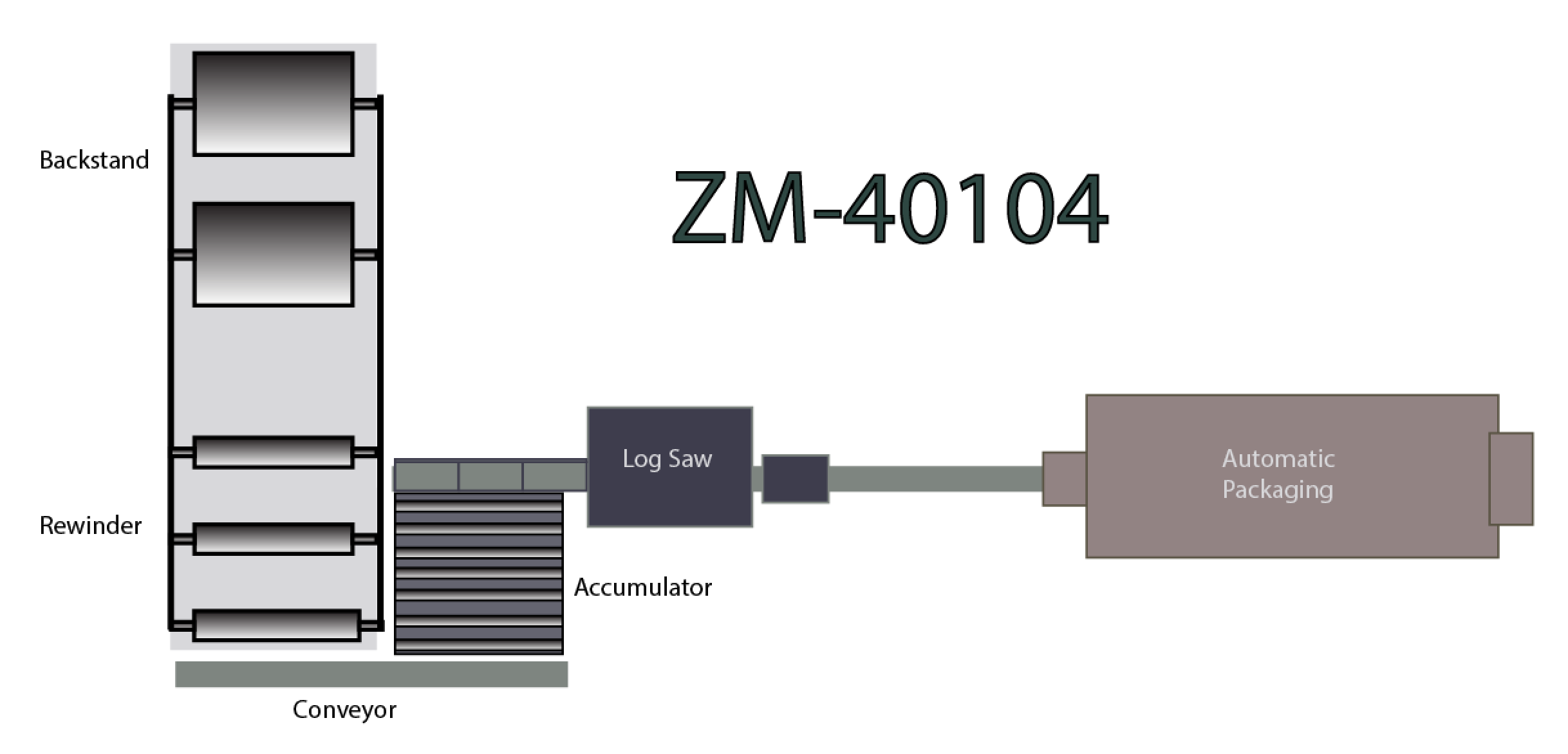

Integrated Toilet Paper Production Line |

|

ZM-OK Log Saw Automatic Toilet Paper Cutting Machine |

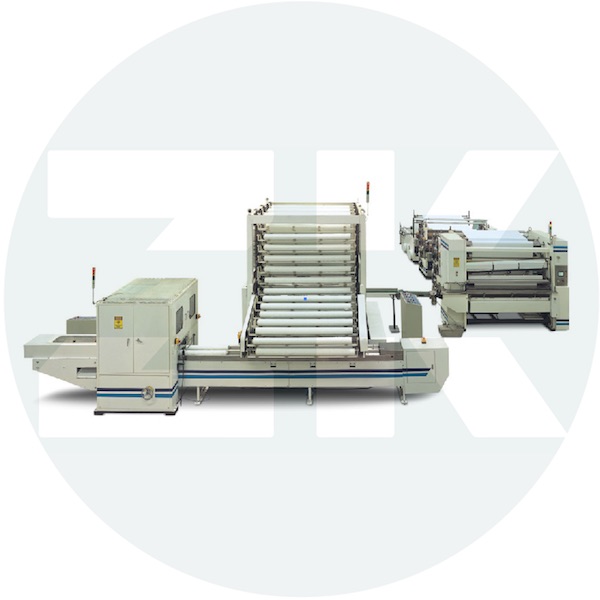

ZM-OK Automatic Log Saw

ZM-OK

Automatic Log Saw

ZM-OK Automatic Log Saw is the equipment for slitting toilet paper and paper kitchen towel roll. With the features of high speed and great efficiency, the machine is your best choice for producing toilet paper and kitchen towel. With servo system adopted, the quality of the product is superior. The machine can have 2 to 4 lines, according to the customer requirement, and it can do 150 cuts per minutes. With the orbital slitting system, the products will not be crushed.

1. The paper roll is clamped by the paper clamp and pushed to the slitting device by the driving unit of the machine. Afterward, it is sent to the slitting blade for cutting. The end product of this machine is smooth and neat, and the machine is highly accurate.

2. This machine is equipped with advanced photoelectric checking system and large diameter whirl slitting knife. It can set the length of the paper head automatically and slice the paper roll accurately. The machine can slit 2 - 4 paper rollers at the same time, and can slit 150 times per minute.

3. The slitting device has an optimized design with the feature of automatic knife sharpening system. The grinding wheel can grind the blade accurately according to the slitting times.

4. The Automatic Log Saw machine has the most advanced PLC programming, servo driving system, whirl and variable frequency speed regulating. The operator can set all required parameters via the computer controlling screen, such as the time and frequency of blade sharpening, and also the slitting speed and length. Therefore, the smoothness and the continuity of pushing, slitting and blade sharpening will be better.

5. Optional dust collector system

6. Optional ends removal system and conveyor system

ZM-OK-VI Log Saw (4 Lanes) |

ZM-OK-IV Log Saw (3 Lanes) |

ZM-OK-III Log Saw |

ZM-OK-I Log Saw (2 Lanes) |

| Model | ZM-OK-VI Log Saw | ZM-OK-IV Log Saw | ZM-OK-I Log Saw |

|---|---|---|---|

| * Paper Roll Length (mm) | 3550/2850/2000 | 3550/2850/2000/1780 | 3550/2850/1780 |

| Lane | 4 | 3 | 2 |

| Machine Speed |

150 cut/min 4 rolls/cut |

150 cut/min 3 rolls/cut |

150 cut/min 2 rolls/cut |

| Operation Speed |

Cutting Length 110mm : 130 cut/min Cutting Length 230mm : 90 cut/min 4 rolls/cut |

Cutting Length 110mm : 130 cut/min Cutting Length 230mm : 90 cut/min 3 rolls/cut |

Cutting Length 110mm : 130 cut/min Cutting Length 230mm : 90 cut/min 2 rolls/cut |

| Power | 18 Kw | 18 Kw | 28 Kw |

| Specifications of Finished Product |

Outer Diameter: 90-160mm Cutting Length: 50-300mm Ends Length: 25-100mm |

||

| Cutting Length Adjusting |

Set on operation panel Tolerance +-1mm (not including both ends) |

||

| Driving Control of Pusher | Driven by Servo Motor | ||

| Blade Grinding | Automatic grinding, pneumatic wheel fix angle grinding, parameters can be programming controlled on operating panel. | ||

| Diameter of Blade | 610mm | ||

| Grinder Feeding | Automatic | ||

| * Clamp |

Replaceable * Please specify dia. of finish product. |

||

| Procedure Control | Siemens PLC | ||

| Functional Forms | Cutter blade is running and spinning, controls the paper logs moving on at the same time. | ||

| Dust collection system | Absorb dust on grinders; exhaust fan exhausts dust and hot air. Supply 10 collection bags. | ||

| * Cooling & Lubrication System | Spray oil on grinding position, parameters can be programming controlled by operating panel | ||

| * Both Ends Removal System | Servo Control, 100% remove ends | ||

| * Cutting Blade Height Adjustment | Manual / Touch Screen Operation Panel | ||

* It shows the specifications that are optional or should be specified while ordering.