Cup Machines are made according to CE standard.

It ensures the low leaking ratio and high quality of paper cups with unique original designed bottom knurling system and single shaft.

Paper sucking system adopt the vacuum pump, big power and stable running.

With unique single shaft design, the drive system is conducted by the stable gear system,it would be more stable when machine running at a high speed.

Equipped with the Schneider PLC micro computer system and Schneider touch screen for easy and visible operation.

The upgraded gear box is for longer life span.

Bearings are either SKF or NSK.

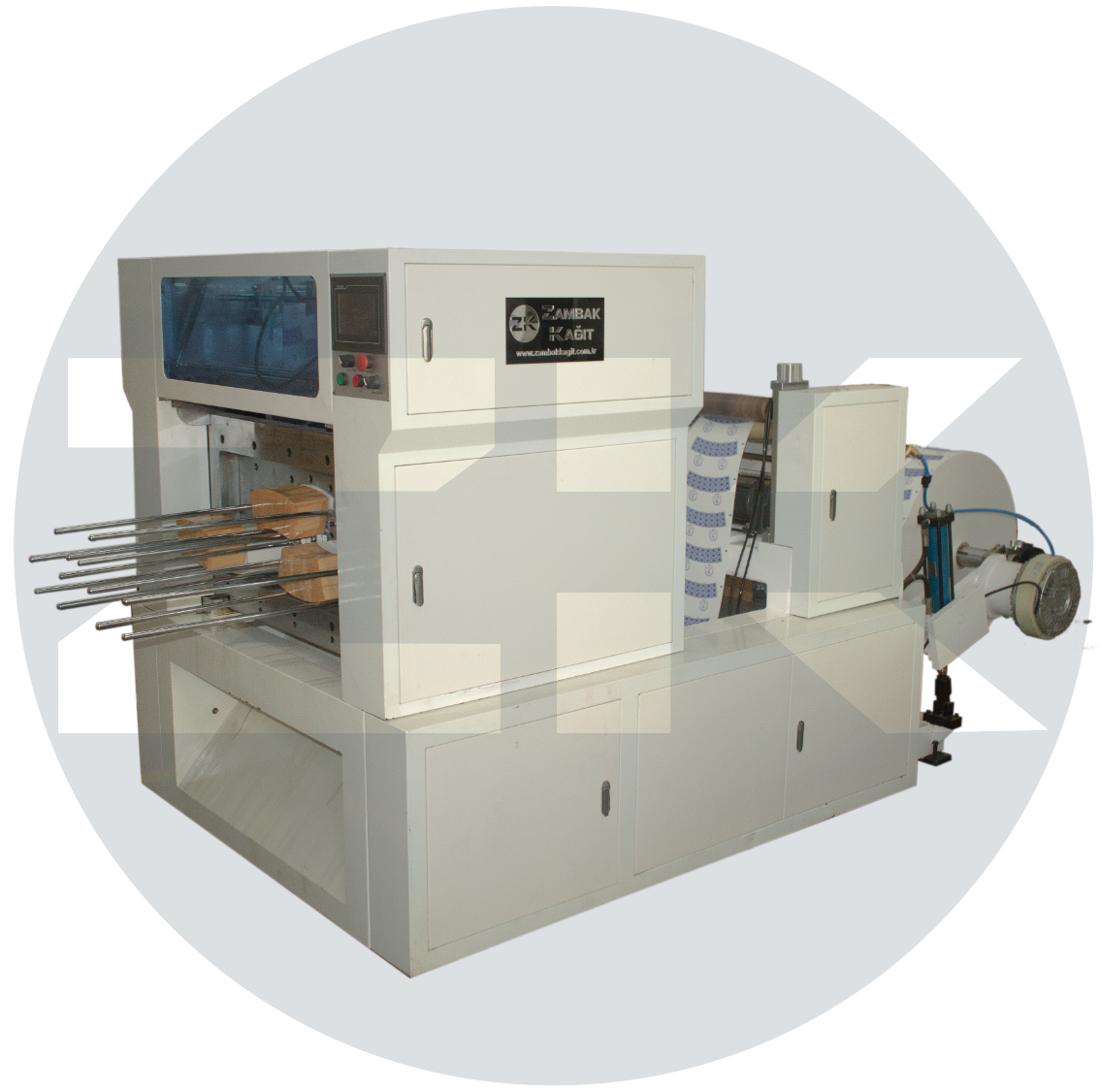

ZKBM

Smart Line High Speed Paper Cup Forming Machine

ZKBM High Speed Paper Cup Forming Machine is adopted with the ultrasonic sealing station, so this model machine can produce various cups for hot and cold beverages, such as ice cream, yogurt, soups and snacks, by using single side or double sides PE coated paper. As one of our most popular models, it has its own compact structure. The machine runs steadily and fast and produces cups with good quality and lowest waste percentage. Therefore, it is the best choice for paper cup producers in terms of price/performance.

The machine comes with an automatic lubrication system and thus all mechanical parts work more properly and smoothly. With automatic lubricating system, it will automaticaly lubricate every moving parts when machine runs.

Paper cups bottom are made with lower mold clamping, which ensures a more uniform base adhesion and a low incidence of leakage problems.

The machine has PLC control with error detection and sensor function. The bottom cardboard feeding is controlled by the servomotor.

The machine has a safety cabinet to ensure the safe operation of the people working on it.

The material of cup mold is adopted aluminum instead of carbon steel, thus it’s lighter which enables the machine to work faster than the general paper cup machine.

The 90-degree revolve transfer cup. It makes the forming cup 100% transferable to mold, reduce the rate of wasting.

The cup bottom can be transferred by one time. It means the cup bottom can be transferred to cup inside, with high precision, which reduces the wastage when transferring the second time.

Due to the revolve curling bottom, contacts and possible damage to the printed and pe coated surface are reduced and also it ensure the equality of bottom curling.

The parts of the machine are well crafted, and therefore every part can be easily exchanged.

The machine has the blowing air system that uses a piece of windpipe for storing the paper cups safely.

Cup Machines are with Ultra Sonic Sealing system.

Paper cup bottom sealing by Leister hot air system, is imported from Switzerland.

Cup Machines are fully automatic with auto counting, auto transfer and auto stacking system.