|

Facial Tissue Production Line-2022 |

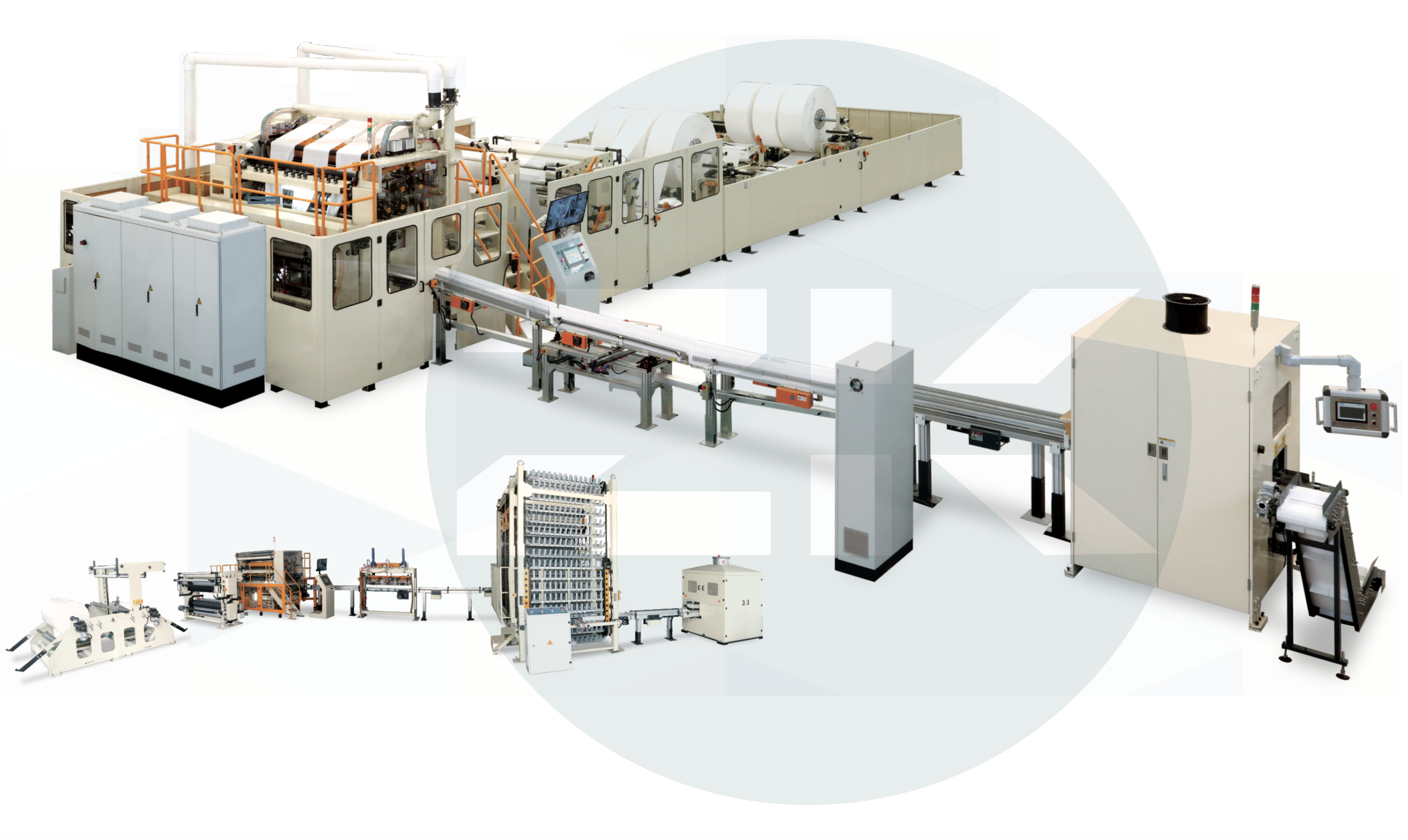

Double Line Facial Tissue Machine |

|

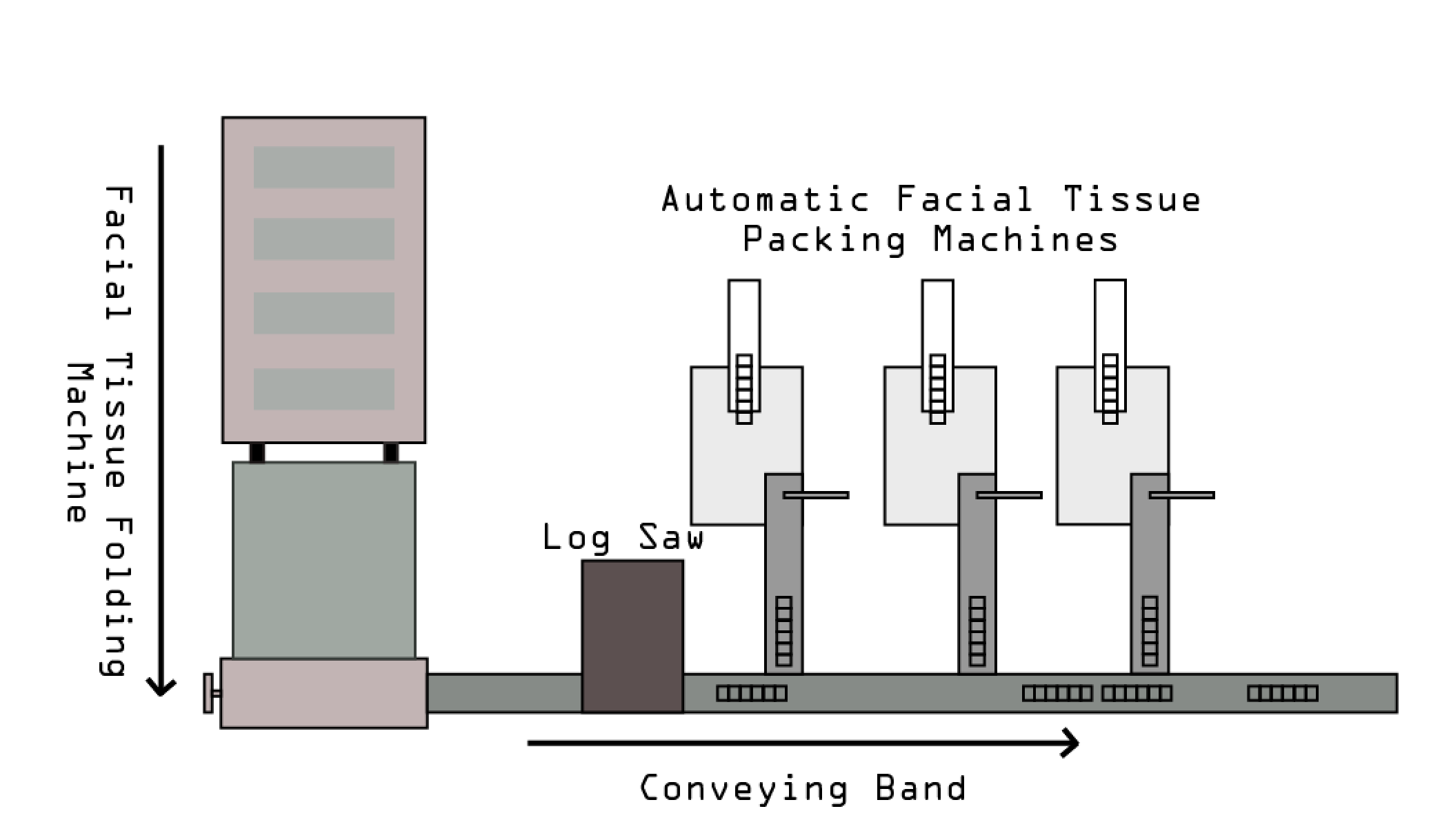

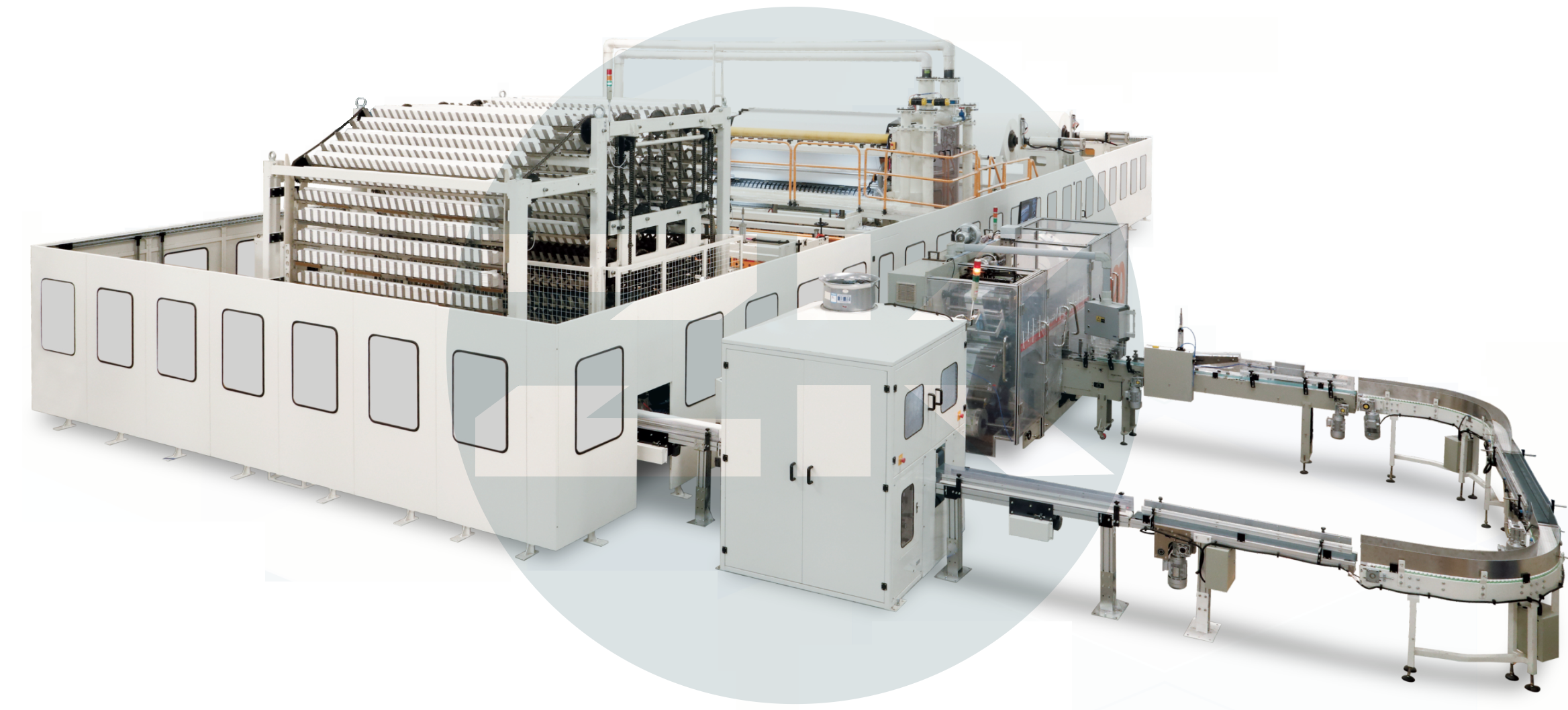

| Facial Tissue Production Line |

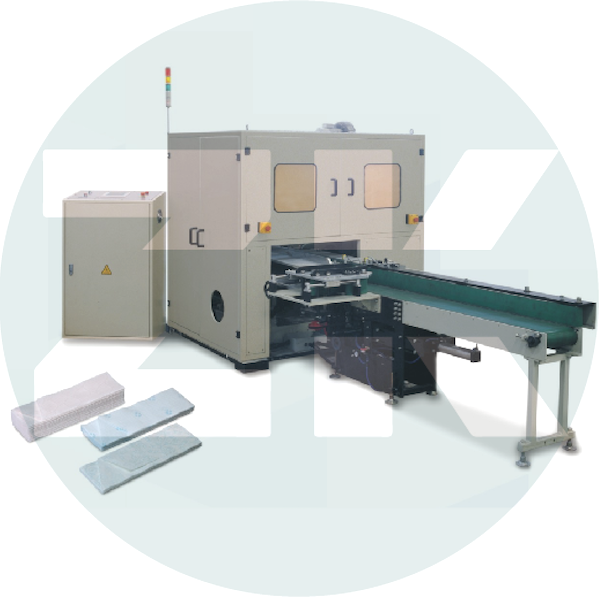

V Fold Machine |

|

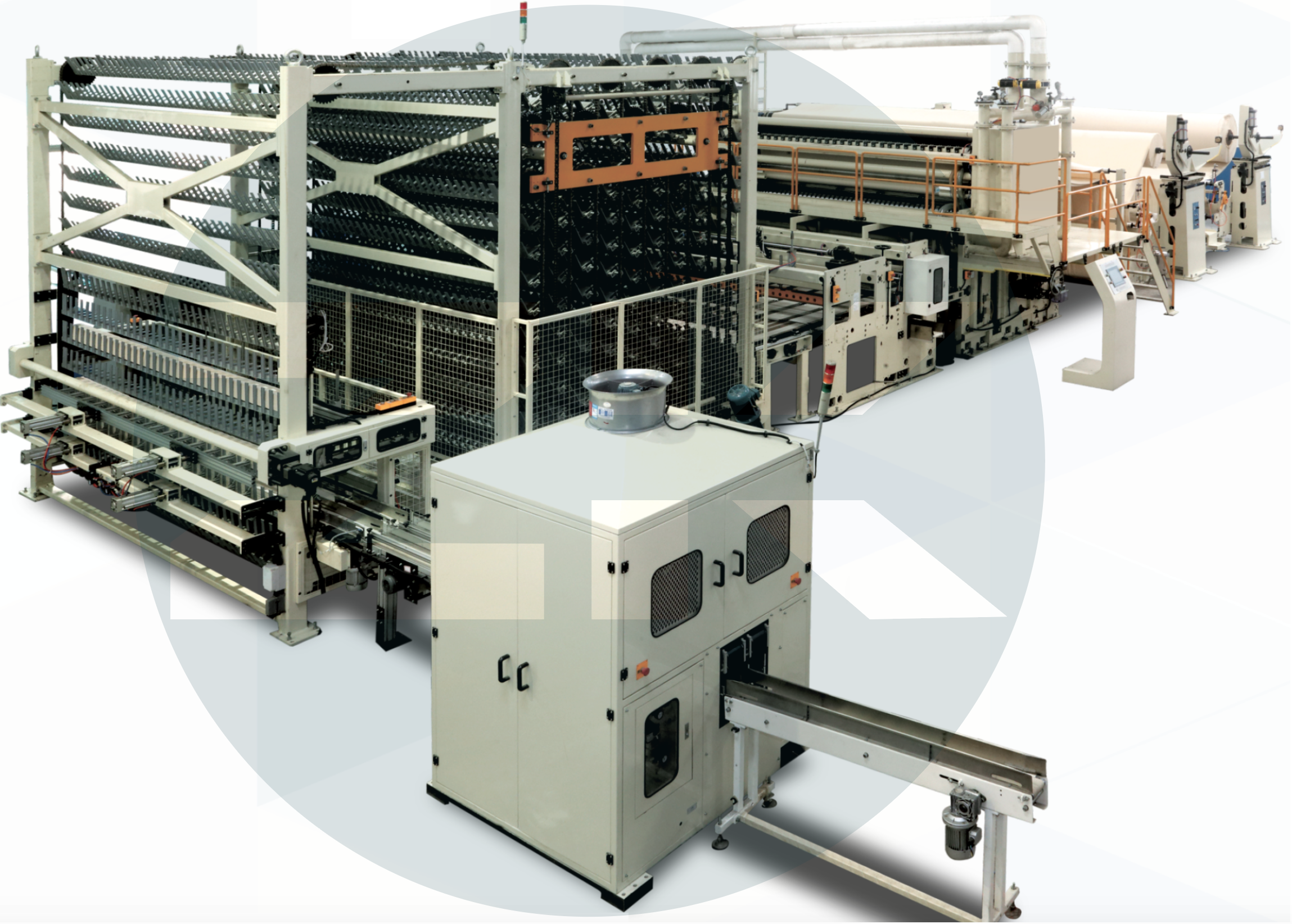

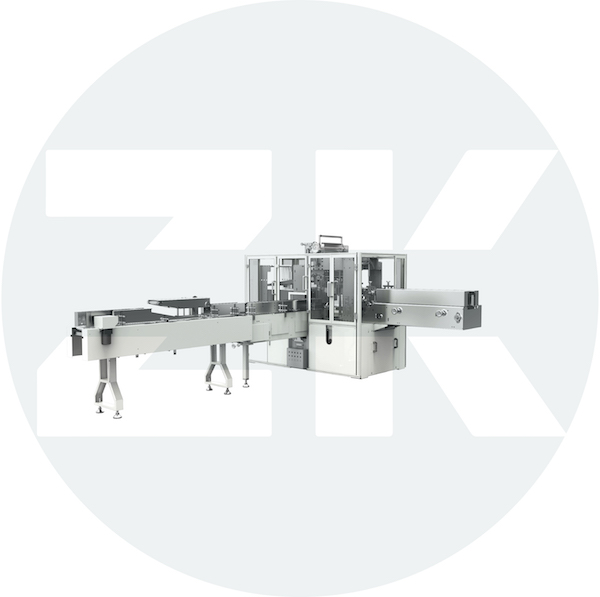

Facial Tissue Production Line with Automatic Transfer |

V Fold Tissue Production Line |

|

Facial Tissue Line with Band Saw |

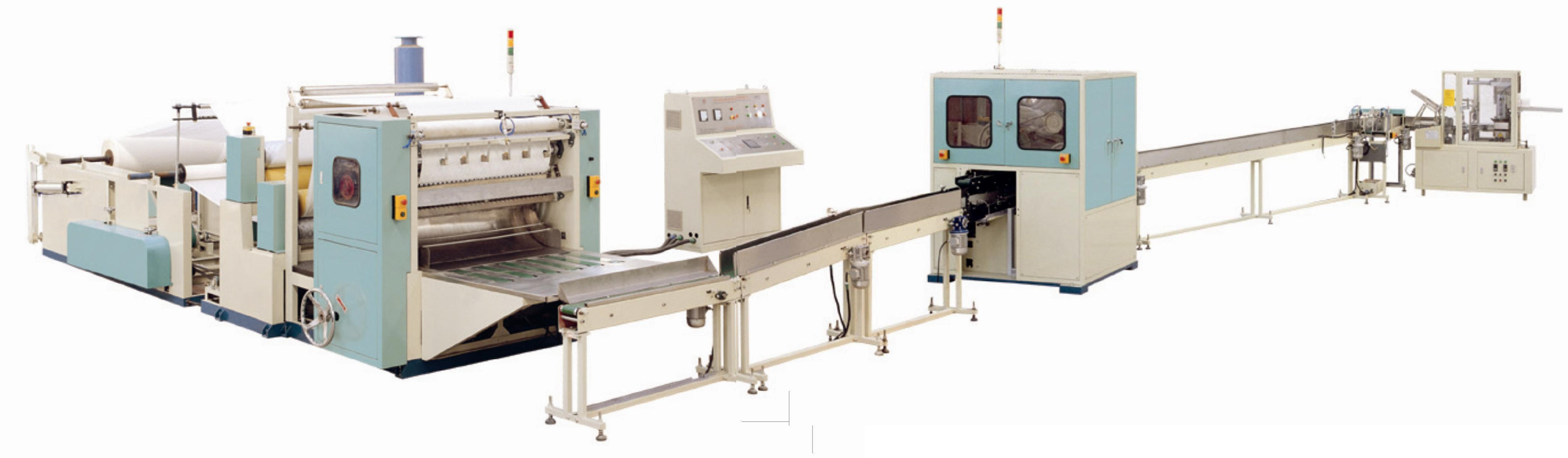

Reference Project: LILA KAGIT, Istanbul, Turkey Facial Tissue Production Line |

|

LILA KAGIT Facial Tissue Production Line |

Facial Tissue Machine - V Folding Machine |

ZM-KM-H Facial Tissue Production Line

ZM-KM-H

Facial Tissue Production Line

With our fully automated facial tissue production line, you can produce high-quality facial tissue products. This production line has the automatic functions of embossing, folding, counting, cutting, dividing, auto-taking, auto-dispatching, auto-transfer, and auto-sealing in one. In addition, it has the advantages of simple operation, high production efficiency, while ensuring the consistency of the finished products. With the fully automatic production, the amount of production labor can be cut down, so you can save from the production and managing costs.

1. Max. The width of the jumbo reel is 2950mm.

2. Horizontal style paper unwind stand: Raw paper line-placed is delivered paper with pneumatic wide belt and separate tension control device in each roll of raw paper. *Optional pneumatic paper loading unit.

3. * Web-edge controlling function: It will be installed on the paper unwind stand. The function is affected by a sensor to inspect and trace the web-edge, which is controlled by PLC. Then the sensor will transfer the data to the web-edge controlling performer to affect the aim of alignment of different paper webs. With this web-edge controlling function, the web edge of the different paper web will be kept in parallel with each other, even if the paper roll is transferring at high speed, which will reduce the wastage of paper roll edge.

4. The machine will alarm when the paper core or stainless steel tube is finished.

5. Auto-dispatching/taking device: This device can fulfill the instruction sent from the system accurately, count and divide the folded paper according to the requirements, and then send it to the dispatching device.

6. *Dispatching device: It's to dispatch and transport the paper sheet to an auto-loading device.

7. Each unit is driven by an independent motor (servomotor). Simple structure decreases the failure rate.

8. Flexible controller arm is more convenience to operate.

9. Patented Technologies: simple and easy to maintain cutting blades & shafts structure and lower blade wastage have a character to protect blades and shafts. Folding roller manufacturing process significantly improves rigidity and vacuum adsorption, while the further effect is better folding accuracy and stability. The trimming top blade structure uses vacuum system to remove trimmed paper

|

Model |

ZM-KM-190A-2950 |

ZM-KM-190A-2050/1500/910 |

|

|

|

|

|

Parent Reel Width |

2950 mm |

2050/1500/910 mm |

|

*Output Direction Cutting Length |

180/190/200/210mm |

180/190/200/210mm |

|

Design Speed |

130 m/min 1300 sheets/min/lane - 2 plies |

130 m/min 1300 sheets/min/lane - 2 plies |

|

Guarantee Operation Speed |

100 m/min 1000 sheets/min/lane - 2 plies |

100 m/min 1000 sheets/min/lane - 2 plies |

|

*Max. Outer Diameter of Raw Paper |

2500/2000/1500mm |

1500mm |

|

*Web Feeding Protection |

Automatic web thickness monitor |

Automatic web thickness monitor |

|

Upper Blade Structure |

Patented Technology |

Patented Technology |

Bottom Blade Structure |

Patented Technology |

Patented Technology |

|

*Drive Type |

Separated Drive |

Separated Drive |

|

Procedure Control |

PLC |

PLC |

|

Folding Type |

V Fold |

V Fold |

*Back-stand |

2-4 plies, with shaft or shaft less type, independent drive |

2-4 plies, with shaft or shaft less type, independent drive |

|

*Embossing |

Steel to Rubber/Felted/Woolen steel roller, independent drive |

Steel to Rubber/Felted/Woolen steel roller, independent drive |

|

*Lamination |

Standard/Medium/High Grade, optional quick-change function |

point to point, nested or others |

|

*Side Trimming System |

Optional |

Optional |

|

*Edge Embossing |

Independent Pneumatic |

Independent Pneumatic |

|

*Counting |

Malposition/Ink |

Malposition/Ink |

|

*Automatic web-tension control system |

Optional |

Optional |

* It shows the specifications that are optional or should be specified while ordering.