Next-Gen Automatic Transfer & Packaging Napkin Machine |

|

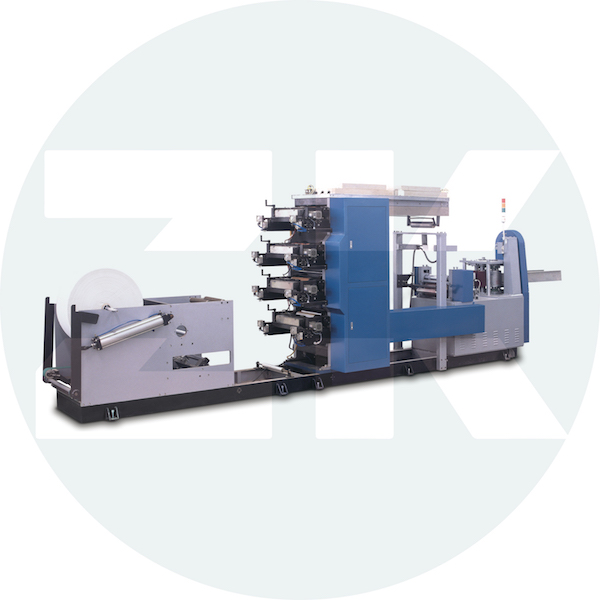

SmartLine Napkin Machine with Printing Unit |

|

|

EVA-PM SmartLine Napkin Machine- ISTANBUL Eurasia Packaging Fair 2017 |

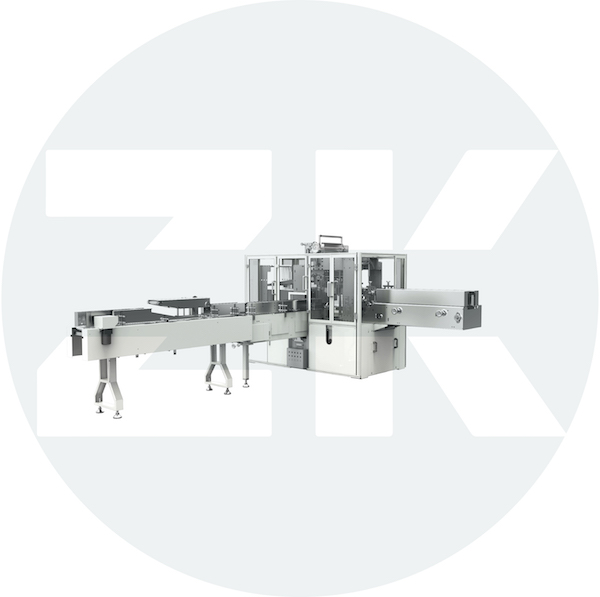

EVA-PM High Speed Napkin Folder and Napkin Packing Machine with Auto-transfer |

|

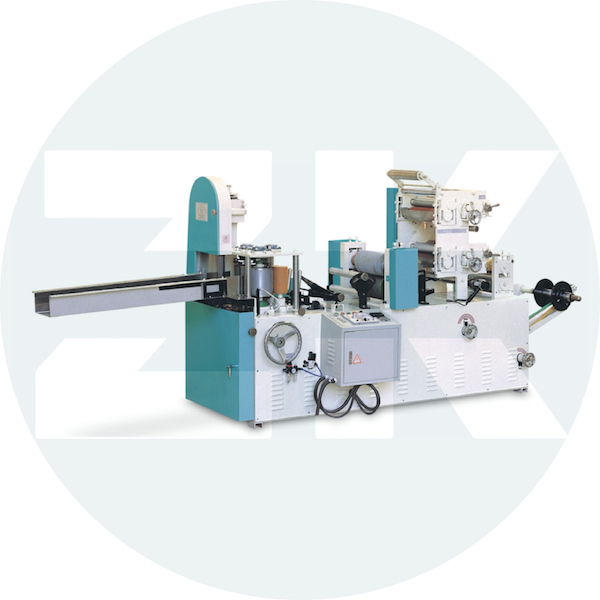

EVA-PM High Speed Napkin Machine |

High Speed Napkin Machine with Embossing |

High Speed Napkin Folder |

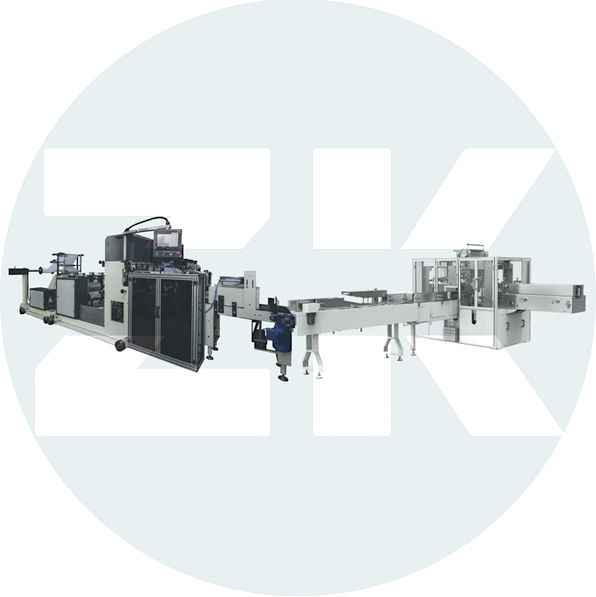

ZK-EVA-PM Fully Automatic Napkin Folder with Auto Transfer and Packing

ZK-EVA-PM

Fully Automatic Napkin Folder with Auto Transfer and Packing

With ZK-EVA-PM model high-speed napkin machines, the paper rolls can be folded and slit into square or rectangle napkins after embossing. The napkins are transferred to the automatic packing machine without any manual interventions. Printing unit can be added if required.

Square Printed Napkin Machine with Automatic Transfer

|

UNWIND STAND |

|

| Max. Roll Diameter | 1400 mm |

| Unwind Stand | 2 2 jumbo rolls can be loaded (1 spare for fast operation) |

| Unwind Belt | 1 |

| Auto Tension Control | Available |

| Unwind Working | Electronic |

| Jumbo Roll Loading | 500 kg |

| Loading | Automatic |

| Tension System | Electronic |

| Edge Control | Auto web guide |

| EMBOSSER UNIT |

|

| Steel Embosser Diameter | 190 mm it could change according to different sizes |

| Steel Embosser Piece | 1 or 2 |

| Paper Embosser Diameter | 190 mm it could change according to different sizes |

| Paper Embosser Piece | 1 or 2 |

| Embosser Pressure | Pneumatic Mechanical |

| Paper Weight (gr/cm3) | 16/19 |

| Emergency Stop Button | Available |

| Booster Pressure Increase | Available |

| Pressure Control | Available |

| Edge Control | Available |

| Embosser Protection | Pneumatic |

| FOLDING UNIT |

|

| Folding Head Diameter | 190 mm it could change according to different sizes |

| Folding Rollers | 2 |

| Folding Size (cm) | 30 x 30 It can also be 30x32 or 30x28 or other customized sizes |

| Emergency Stop | Auto control |

|

| GENERAL SPECIFICATIONS |

|

| Capacity (max.) | 2000 napkins/min. |

| Power (Main Motor) | 5,5 KW |

| Power (Unwind Unit) | 1,1 KW |

| Power Supply | 380 V, 50 Hz |

| Air Pressure | 8 bar |

| Air Consumption | 150 lt/min |

| Operating Temperature | 40 ˚C max. |

| Control System | Electronic unwind/folding/transfer, all units work with individual drive/motors |

| Auto Alarm System for Problems on Machine | Available |

| Web Guide | 2 edge control units |

| Transfer Unit | Finger System |

| USED MATERIALS |

|

| Embossing Pattern Processing | Laser |

| Bearings | FAG or SKF |

| Pneumatic Parts | PEMAKS |

| Electronic Parts | LG, SCHNEIDER |

| Aluminum Quality | 7075 Series |