Industrial Dispenser Napkin Machine |

Dispenser Napkin Folder |

Dispenser Napkin Machine |

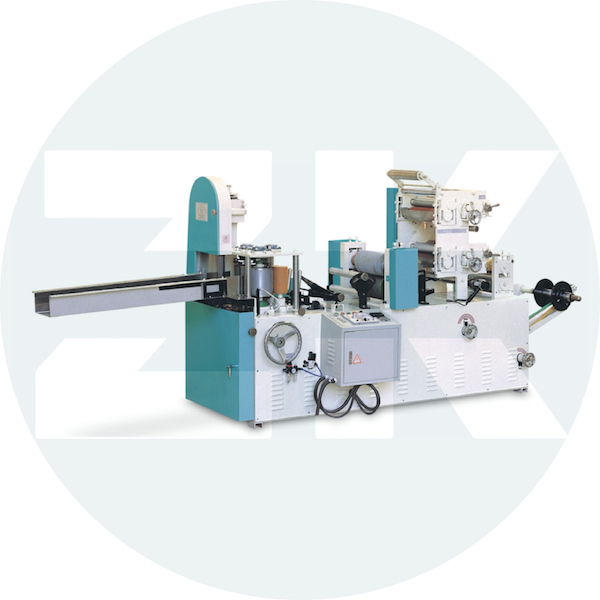

ZM-PM-D Dispenser Napkin Machine

ZM-PM-D

Dispenser Napkin Machine

ZM-PM-D Air Suction Dispenser Napkin Processing Machine adopts vacuum suction technology to process napkin paper after embossing and folding. The last fold is a little bit longer so that it is easy to be drawn from the box, and the other paper sheet won't be drawn out together, so the end user can avoid the unnecessary wastage. The napkin machine has an electric monitor tracking the output of paper, automatic stop device for the broken paper and an automatic counting and dividing device. It even adapts to the inverter speed regulator enabling a simple operation.

|

Model |

ZM-PM-D Dispenser Napkin Machine |

|---|---|

|

Folding Type |

Interfold 3 Fold |

|

Max. Machine Speed |

1400 pc/min |

|

Power |

4 KW |

|

* Raw Paper |

Can differ according to different sizes and types of the machines |

|

Inner Core Diameter of Raw Paper |

76,2mm |

|

Raw Paper Material |

One layer napkin, GSM 22-40g/m2 |

|

* Embossing |

Steel to steel embossing |

|

* Web-edge Controller |

Automatic |

|

Counting |

Automatic |

|

* Printing System |

Flexo printing with aniline plate |

|

Main Transmission |

Variable frequency speed regulating |

|

* Packing Size |

It will be different according to different type and the configuration of the machine |

* It shows the specifications that are optional or should be specified while ordering.