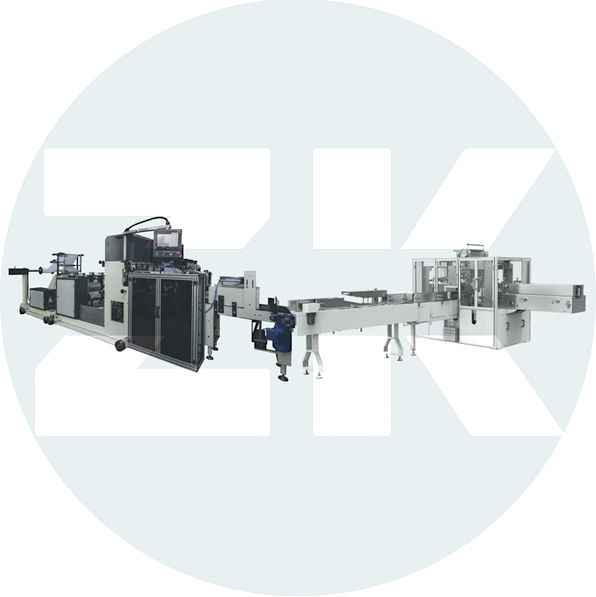

SmartLine Napkin Machine with Printing Unit |

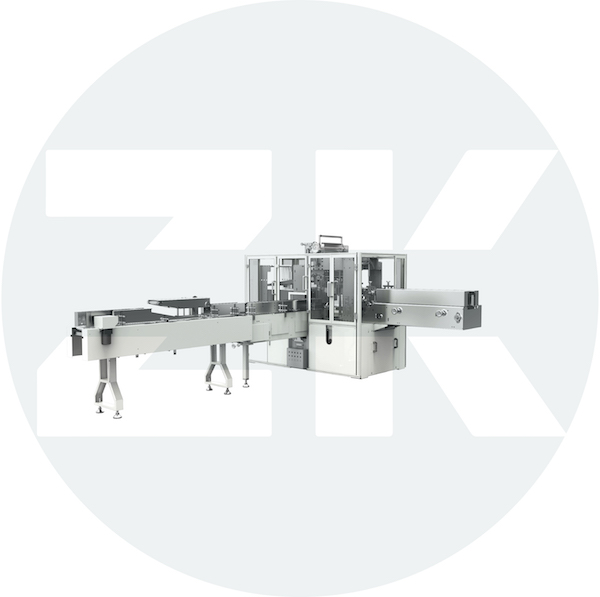

4 Colors Printed Napkin Machine with Packing |

|

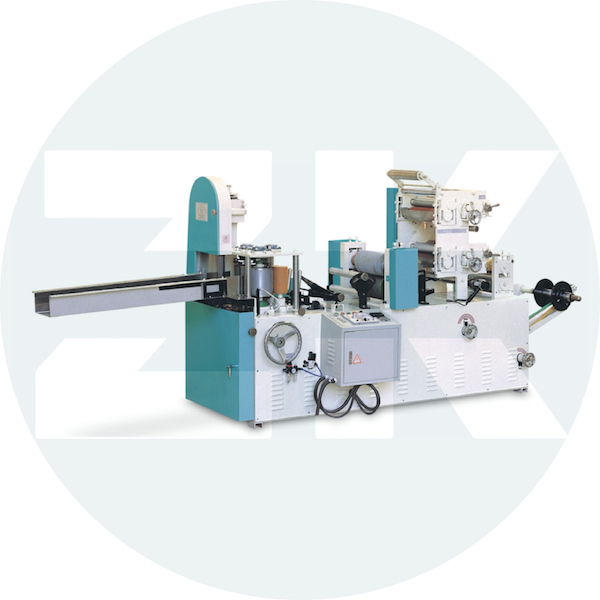

Four Colors Printed Napkin Machine |

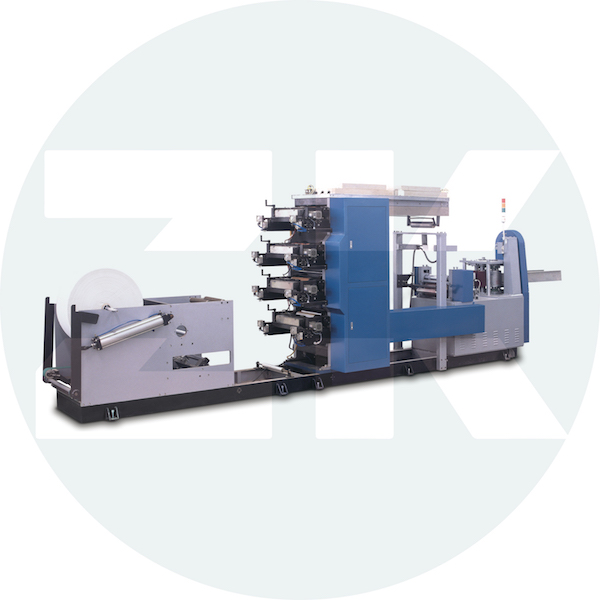

ZM-PM-III Four Colors Printed Napkin Machine

ZM-PM-III

Four Color Printed Napkin Machine

With ZM-PM-III model paper napkin machine, the slitted paper roll can be printed with a variety of colorful and fine patterns, and then be folded and slitted into square or rectangle napkin after embossing.

1. With professional net-pattern color printing ink roller on the color printing system, the patterns printed by this device will have a better effect.

2. The raw paper will be sent to the polishing unit by synchronized belt, and sent to the embossing roller after polishing. Tension regulators are set between raw paper, polishing and embossing device.

3. Automatic stop protector for paper wind around the folding wheel.

4. Automatic web-edge controller.

5. Automatic constant temperature drying device.

6. Automatic stop protection for broken paper, automatic speed reducer for jumbo roll used-up gradually, automatic stop protector for paper wind around the folding wheel.

7. The electric overprinting device at 360 degree.

8. Water and ink circulator.

9. Fully automatic paper roll unwinding system: With computer tracking the moving speed of the machine and transferring the data to the servo system, the servo system conveys the paper sheet to printing system accurately, according to the instruction from the computer. This makes the overprinting more accurate and will have better printing effect.

10. *Online video monitor system for printing unit: With this system, the printing status can be displayed in real time, and can supply online video information for overprinting, which can ease the labor intensity, increase work efficiency, and reduce waste products.

11. *Embossing with engraving mode can be equipped, which can make engraving patterns clearer and they’ll have a stereo effect.

|

Model |

ZM-PM-III Napkin Machine with Four Colors Printing |

|---|---|

|

* Max. Width of Raw Paper |

240/300/330mm |

|

Max. Diameter of Raw Paper |

1100 mm |

|

* Max. Inner Core Diameter |

3", 76mm |

|

*Folding Types |

1/4, 1/8 |

|

* Finished Product Size |

240mm x 240mm |

|

Raw Paper Specs |

2-3 plies, GSM 18-25g/ply |

|

Speed |

160-180 m/min |

|

Power |

Variable Frequency Speed Regulating |

|

Procedure Control |

PLC |

|

* Counting |

Electronic, Pneumatic |

|

* Heating System |

Resistance can be added if required |

|

* Flexo Printing |

Water based ink, aniline layer |

|

* Edge Control |

Optional |

|

* Automatic Paper Tension Control |

Can be added if desired |

|

* Video Surveillance System |

Can be added if desired |

* It shows the specifications that are optional or should be specified while ordering.