Paper Tube Making Machine - Spiral Winding |

High Speed Spiral Paper Tube Machine |

Spiral Paper Core Making Machine |

Automatic Paper Tube Rewinder and Accumulator |

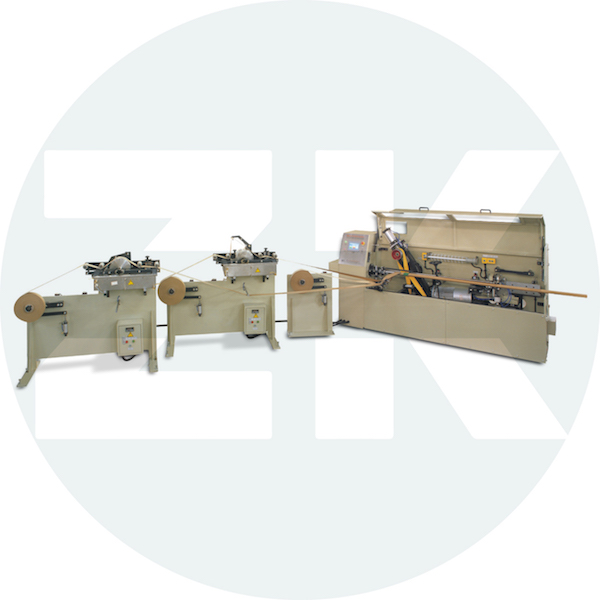

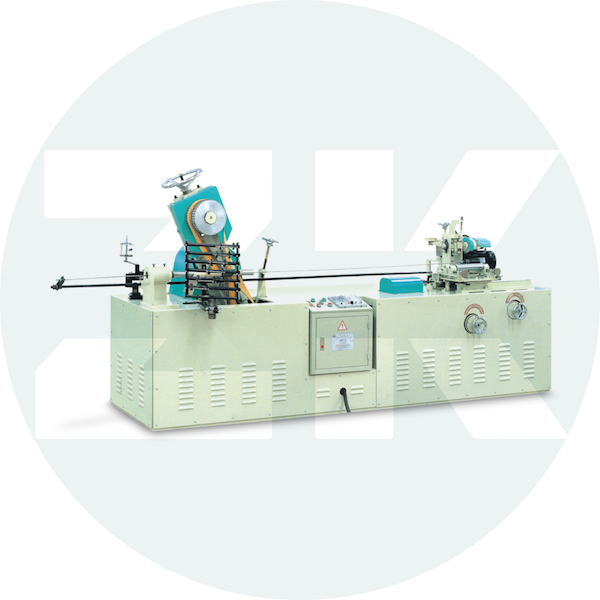

ZK-MM-III Paper Core Winding Machine

ZK-MM-III

High Speed Paper Core Winding Machine

ZK-MM-III Paper Core Winding Machine is a professional machine for producing paper tubes. The machines uses the synchronous slitting principle and has the advantages of high speed, length-adjustable, less length-tolerance, energy saving, self-drying, low noise, tight winding and neat slitting edge. It is the first choice for professional toilet roll rewinding factories and paper processing factory to increase the efficiency and paper roll quality.

|

Model |

ZK-MM-III |

|

Max. Liner Speed of Core Forming |

Max. 60m/min |

|

Max. Liner Speed of Paper Feeding |

Max. 118m/min |

|

Finished Core Inner Diameter |

40-50mm |

|

Finished Core Layer |

2-4 ply |

|

* Winding Shaft Diameter |

40-50mm (size should be specified ) |

|

Parent Reel Width |

65-85mm |

|

Parent Reel GSM |

180-350g/m² |

|

Parent Reel Max. Diameter |

Max. 1000mm |

|

Parent Reel Core Inner Diameter |

3”(76.2mm) |

|

Parent Reel Unwind Stand Qty |

3 |

|

Base Paper Unwind Stand Qty |

1 |

|

Base Paper Auto-lubrication Unit |

Include |

|

Base paper GSM |

80g/m² |

|

Finished Core Length Error |

±2mm |

|

Power Source |

380V, 50Hz |

|

Power Controlled |

110V, DC24V |

|

Air Pressure |

Min. 0.45 Mpa ( 4.5 kgf/cm² ) |

|

Air Consumption |

250L/shift |

|

Earthing Wire |

≤4Ω |

|

General Power |

15KW |

|

Machine Dimension |

(L*W*H) 2900*700*1500mm |

|

Machine Weight |

About 1.8 T |